If you’re trying to get pregnant, you might be wondering about equate pregnancy tests. These tests are designed to help you determine whether or not you are pregnant, and they can be purchased over the counter at most pharmacies.

To use an equate pregnancy test, you will need to collect a urine sample and then dip the test strip into the urine. The strip will change color if it detects the presence of HCG, which is a hormone that is produced during pregnancy. While equating pregnancy tests are generally accurate, it’s important to note that they can give false positive or false negative results in some cases. If you get a positive result on an equate pregnancy test, it’s best to confirm it with a blood test or ultrasound.

First, you’ll need to purchase a home pregnancy test kit. These are available at most drugstores and grocery stores. Once you have your kit, follow the instructions carefully.

Most equate pregnancy tests work by detecting the presence of the hormone human chorionic gonadotropin (HCG) in your urine. HCG is produced by the placenta shortly after fertilization and is present in your body if you’re pregnant. To use the test, simply urinate on the absorbent tip or collect your urine in a clean cup and dip the tip into the urine. Be sure to read the instructions that come with your particular test so that you understand how long to wait for the results.

In most cases, the equate pregnancy test will give you a result within minutes. If the test is negative, it means that there is no HCG present in your urine and you’re not pregnant. If the test is positive, it means that HCG is present and you’re likely pregnant. However, it’s important to remember that a home pregnancy test is not always accurate. If you think you might be pregnant, it’s best to see your doctor for a confirmatory blood test.

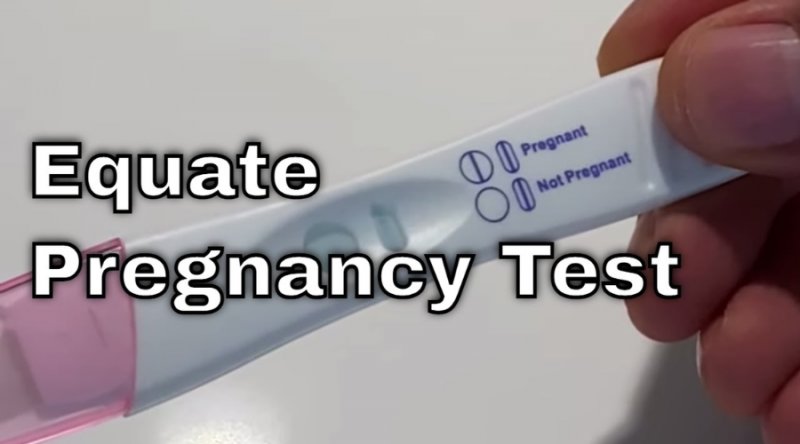

Equate Pregnancy Test instructions

- Remove the test stick from the wrapper.

- Use the thumb grip to hold the test stick by the pink end. Place the absorbent tip in your urine stream for 5 seconds only.

- Replace the cap on the test stick, making sure that the arrows on the cap and stick line up.

- Lay the test stick on a flat surface with the result window facing up.

- Wait for 5 minutes or until the control line appears in the result window. If no control line appears within 10 minutes, the test is invalid and you should retest using a new test stick.

- Read your results! One line means pregnant and two lines mean not pregnant.

If you think you might be pregnant, it’s important to take a pregnancy test as soon as possible. Home pregnancy tests are easy to use and give accurate results. The equate Pregnancy Test is a simple and effective way to find out if you’re pregnant. Follow the instructions carefully and you’ll be able to get accurate results in just a few minutes.

https://babu88-in.com/casino/